SERVICES

WHAT WE CAN DO

CONSULTANCY AND TECHNICAL STUDY

The technical office of EVO offers a professional CONSULTING SERVICE and a production capacity that allows you to RUN THE PROJECTS IN QUICK TIMES. Thanks to twenty years of collaboration with companies in the electronics industry, EVO technicians know the welding and testing processes of electronic boards. The development of numerous projects has given them the experience to propose effective solutions for multiple applications. EVO performs FREE FEASIBILITY STUDIES and PROVIDES SIMULATIONS that allow the client to evaluate the effectiveness of the proposed solution. This SERVICE REDUCES ERROR PROBABILITY AND SAVES TIME AND MONEY.

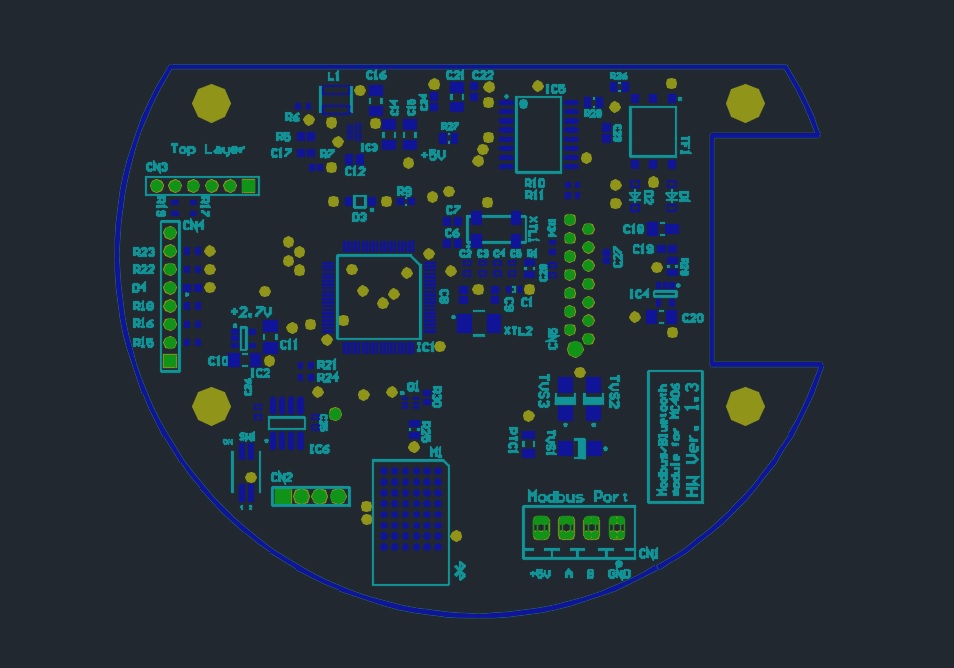

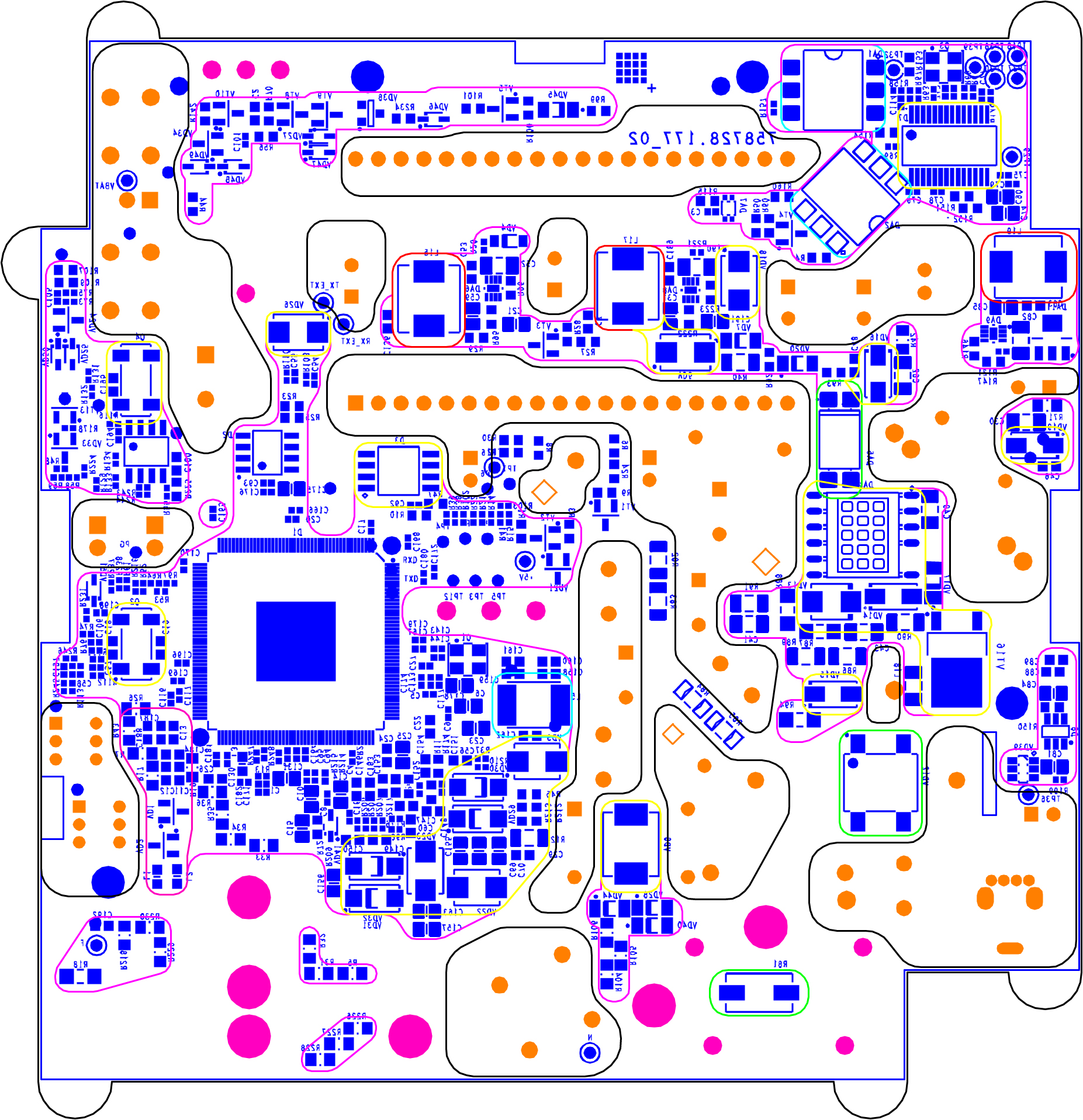

EVO has software with which the gerber files of all electronic cards are processed. THE INFO CONTAINED IN THE FILE GERBER, TOGETHER WITH THE INDICATIONS ON THE THICKNESS AND THE DIMENSIONS OF THE COMPONENTS, ARE SUFFICIENT TO DEVELOP THE PROJECT OF A MASK or of an equipment, even in the absence of the physical sample of the card. This service allows the customer to anticipate the development of the equipment when the first samples of the cards are not yet ready. The documentation that is provided allows him to evaluate the suitability of the project.

EVO performs a wide range of machining operations with numerically controlled machining centers and produces in its workshop almost all the details that make up the equipment supplied to customers. We also carry out work on behalf of third parties and create custom-designed parts in composite, plastic, phenolic, metal, and titanium materials.

Together with all EVO equipment, IT PROVIDES, INCLUDED IN THE PRICE, a COMPLETE DOCUMENTATION that includes the omplessive design of the equipment with the bill of materials of its components, and the quoted and codified drawings of the components themselves. When it is necessary to clarify the most critical details of an equipment, EVO PROVIDES FURTHER 3D VIEWS that highlight the shapes and dimensions of the components and their operating system. The contractor receives a PREVIEW OF THE EQUIPMENT, and the elements to assess its suitability and interact with our technical department.</p> <p>For example, when developing a welding mask, an image is sent to the client showing the screen printing of the bottom card overlaid on the mask. The visual impact it receives is equivalent to inserting the physical card into the pallet and allowing it to check the suitability of the welding mask. These cues create interaction between customer and EVO designers, reduce errors and misunderstandings. The customer can create an archive with drawings and documentation provided by EVO. Thanks to the coding system, it easily traces the drawings of the assemblies and the details that compose them, it is easier to specify changes due to revision of the board and to request replicas of components.